From Hand-Turned to High-Precision: Our Journey Towards the Perfect Pen

When I first started the “XiaoZhuo” (小拙) project, my vision was simple: to create a wooden fountain pen that didn’t feel like a clumsy craft, but a refined writing instrument.

Phase 1: The Lesson of the Hand

In the beginning, like many independent brands, we collaborated with skilled woodworkers. There is a romantic notion about “fully handmade” products, and indeed, those early pens had character. However, as a pen enthusiast myself, I faced a harsh reality. While handmade turning is artistic, it lacks standardization. Tolerances varied from pen to pen. More importantly, the airtightness of the cap—the most critical feature for a fountain pen to write instantly—was hard to guarantee consistently with traditional methods. I realized that “warmth” should not come at the expense of “performance.”

Phase 2: The Power of Industrial Precision

Early in 2025, we made a bold move. We partnered with a professional machining factory to produce our pens using high-precision CNC lathes. The results were exhilarating. The dimensional accuracy was perfect. The polishing was exquisite. The airtight structure finally worked flawlessly every single time. We solved the functional problems.

But new problems emerged. A factory is a place of efficiency, not art. When mass-producing, the machine treats every piece of wood the same.

- The Challenge: Wood is alive. Its grain twists and turns. For consistent woods like Red Sandalwood, the factory does a great job. But for dramatic woods like Bocote or Olive, the factory’s standardized cutting path often ignored the natural flow of the grain, sometimes cutting away the most beautiful patterns.

Phase 3: Taking Control (The Hybrid Model)

I realized that to achieve the perfect balance between “Industrial Precision” and “Natural Beauty,” I needed to take control into my own hands.

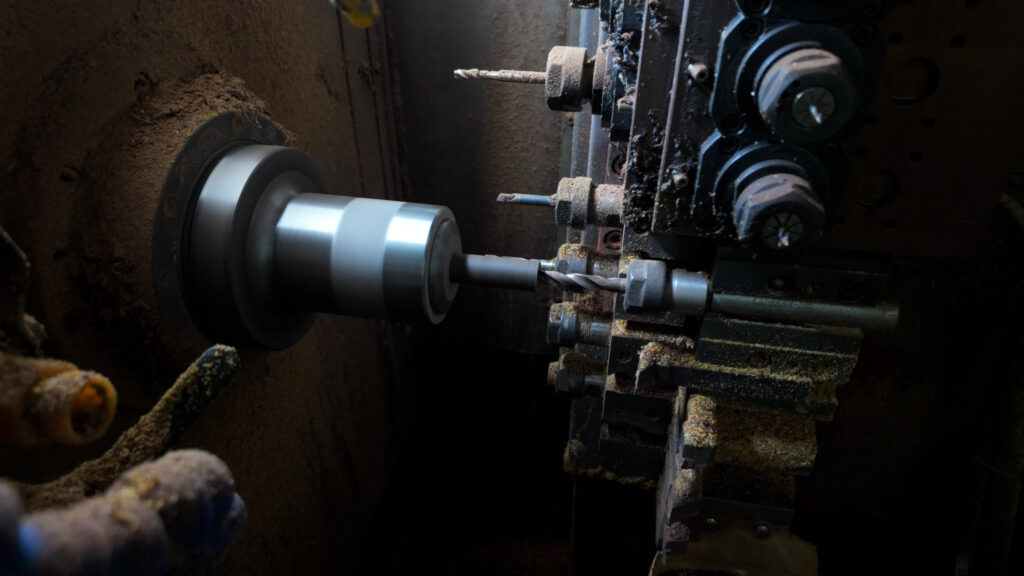

So, I made a significant investment. I purchased my own high-precision small CNC lathe (as shown in the photos) and set it up in my own studio.

This machine changes everything. It allows us to adopt a “Hybrid Manufacturing” philosophy:

- For Complex Grains: I now machine the special, highly figured woods personally in my studio. I can adjust the cutting path to highlight the best grain patterns, ensuring the soul of the wood is preserved.

- For R&D: I can now prototype new structures, test new materials, and iterate designs in hours, not weeks.

- For Stability: We continue to work with our factory partners for the standardized, mature parts of our production, ensuring consistent quality for our core lineup.

The Future of SIMEICHU (四美具的未来) This machine represents more than just a tool; it represents our commitment. We are willing to spend the time and capital to bridge the gap between the Maker’s Spirit and Modern Engineering.

When you hold a XiaoZhuo pen, you are holding a product that has the reliability of a machine, but the heart of a human.

Thank you for being part of this journey.

— Founder, SIMEICHU